In the realm of gas chemical processing, particularly within synthetic ammonia units, the role of catalysts and adsorbents cannot be overstated. These materials are pivotal in optimizing chemical reactions, improving yield, and reducing energy consumption. While traditional catalysts like iron and ruthenium have long been the mainstay in ammonia synthesis, the exploration of other catalysts is gaining momentum, promising to revolutionize the industry.

The Importance of Catalysts in Ammonia Synthesis

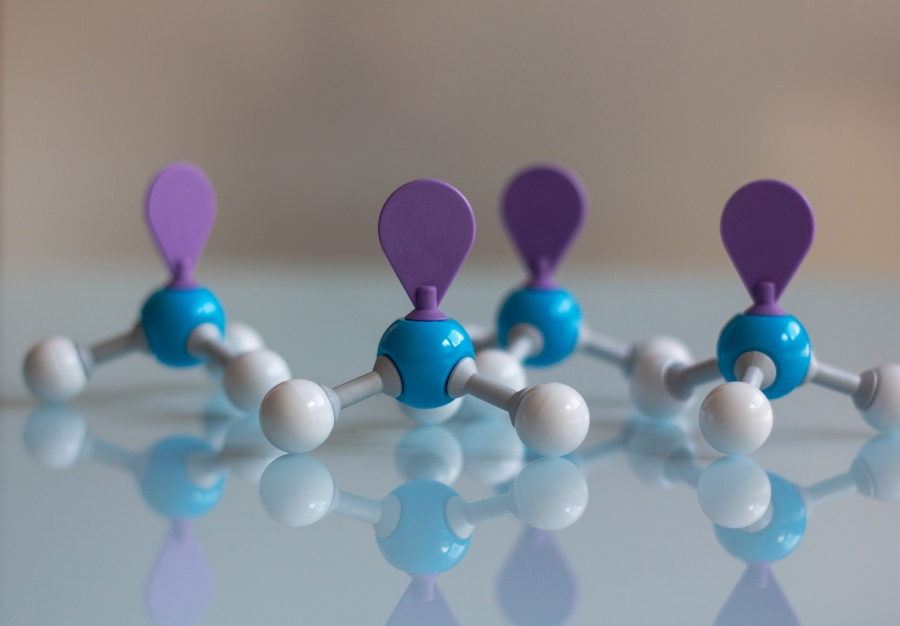

Synthetic ammonia, a cornerstone of the agricultural industry, is primarily produced through the Haber-Bosch process, which combines nitrogen and hydrogen under high pressure and temperature. Catalysts facilitate this reaction, significantly lowering the energy barrier and increasing the reaction rate. However, as the demand for ammonia continues to rise, there is an urgent need to enhance the efficiency of this process. This is where the exploration of alternative catalysts comes into play.

Emerging Catalysts: A New Frontier

Recent research has highlighted several promising alternative catalysts that could potentially outperform traditional options. For instance, transition metal carbides and nitrides have shown remarkable activity and stability under the harsh conditions of ammonia synthesis. These materials not only offer high catalytic performance but also present a more sustainable option by utilizing abundant raw materials.

Additionally, the development of bimetallic catalysts, which combine two different metals, has opened new avenues for enhancing catalytic activity. By fine-tuning the composition and structure of these catalysts, researchers are discovering ways to optimize their performance, leading to higher ammonia yields and lower energy requirements.

The Role of Adsorbents in Enhancing Catalyst Performance

In conjunction with catalysts, adsorbents play a crucial role in gas chemical processing. They are used to capture and remove impurities from the feed gases, ensuring that the catalysts operate under optimal conditions. The integration of advanced adsorbents can significantly improve the overall efficiency of synthetic ammonia units. For example, zeolites and metal-organic frameworks (MOFs) are being investigated for their ability to selectively adsorb specific gases, thereby enhancing the purity of hydrogen and nitrogen feeds.

Sustainability and Economic Viability

As the global focus shifts towards sustainability, the development of alternative catalysts and adsorbents is not just a technical challenge but also an economic imperative. The adoption of more efficient materials can lead to reduced operational costs and lower carbon emissions, aligning with the industry’s goals for greener production methods. Furthermore, the potential for recycling and reusing these materials adds an additional layer of sustainability, making them attractive options for modern ammonia production facilities.

Conclusion: A Catalyst for Change

The exploration of other catalysts and adsorbents in gas chemical processing, particularly in synthetic ammonia units, represents a significant opportunity for innovation. By embracing new materials and technologies, the industry can enhance efficiency, reduce environmental impact, and meet the growing global demand for ammonia. As research continues to advance, the future of ammonia synthesis looks promising, with the potential for breakthroughs that could reshape the landscape of gas chemical processing.

In summary, the journey towards more efficient and sustainable ammonia production is well underway, and the role of alternative catalysts and adsorbents will be pivotal in driving this transformation. As we look to the future, the integration of these innovative materials will not only enhance productivity but also contribute to a more sustainable and economically viable chemical processing industry.

Post time: Oct-22-2025