OEM Customized Ethanol Drying - Molecular Sieves – Gascheme

OEM Customized Ethanol Drying - Molecular Sieves – Gascheme Detail:

| Applications | Material | Size (mm) | Shape | |

| 3A(GC-328) | Drying of natural gas and hydrocarbon streams | Zeolite | 1.6~2.5 | S |

| 3A(GC-335) | Drying of natural gas and hydrocarbon streams | Zeolite | 3~5 | S |

| 3A(GC-341) | Drying of cracked gas and hydrocarbon streams | Zeolite | 1.6 and 3.0 | E |

| 4A(GC-412) | Drying of solvents | Zeolite | 0.5~1.0 | S |

| 4A(GC-428) | Drying of natural gas and hydrocarbon streams | Zeolite | 1.6~2.5 | S |

| 4A(GC-437) | Drying of air, natural gas and hydrocarbon streams | Zeolite | 4~6 | S |

| 4A(GC-441) | Drying of natural gas | Zeolite | 1.6 and 3.0 | E |

| 5A(GC-528) | Natural gas sweetening, Purifying of H2 | Zeolite | 1.6~2.5 | S |

| 5A(GC-528C) | Removal of H2S and light mercaptans from Natural gas, CO/.CO2 from H2, N2/O2 seperation | Zeolite | 1.6 and 3.0 | E |

| 5A(GC-532) | Separation i/n paraffins | Zeolite | 2~3 | S |

| 5A(GC-532A) | Natural gas sweetening | Zeolite | 3~5 | S |

| 13X(GC-928) | Drying and sweetening of natural gas andLPG streams, air purifying | Zeolite | 1.6~2.5 | S |

| 13X(GC-935) | Drying and sweetening of natural gas, air purifying | Zeolite | 3~5 | S |

| 13X(GC-938) | Drying and sweetening of natural gas, air purifying | Zeolite | 4~6 | S |

| 13X(GC-941) | Drying and sweetening of natural gas andLPG streams, air purifying | Zeolite | 1.6 and 3.0 | E |

| 13X-HP | Seperation i/n paraffins, PSA O2 | Zeolite | 1.6~2.5 | S |

| XH-5 | Refrigerant R600a,R290,R12,R123,R124,R125 | Zeolite | 1.6~2.5 | S |

| XH-7 | Refrigerant R290,R12,R123,R124,R125,R134a | Zeolite | 1.6~2.5 | S |

| XH-9 | Refrigerant R123,R124,R125,R134a,R143a,R152a | Zeolite | 1.6~2.5 | S |

Remark

Shape: S-sphere E-cylindrical extrudate

Form: 1-Oxide

Our molecular sieves can satisfy your applications for Cryogenic air separation units (ASUs) are built to provide nitrogen or oxygen and often co-produce argon, natural gas dehydration and sweetening, hydrogen purifying in PSA processing, medical & industrial oxygen in PSA/VPSA processing, air braking system. dehydration of hydrocarbon gas or liquid (No Olefins Present), dehydration of hydrocarbon gas or liquid (With Olefins Present), isomerization processes, Feedstock Purification, LPG Desulfurization,

n/i-Paraffin separation, butane destenching, MTBE / TAME, reformer applications, FCC off gas dehydration.

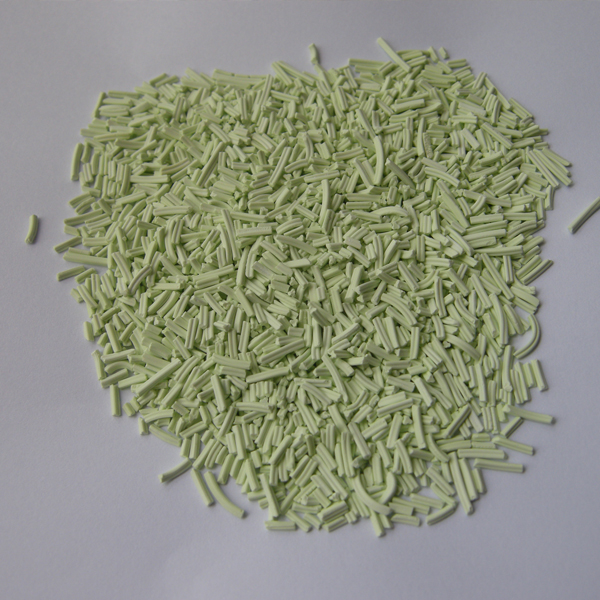

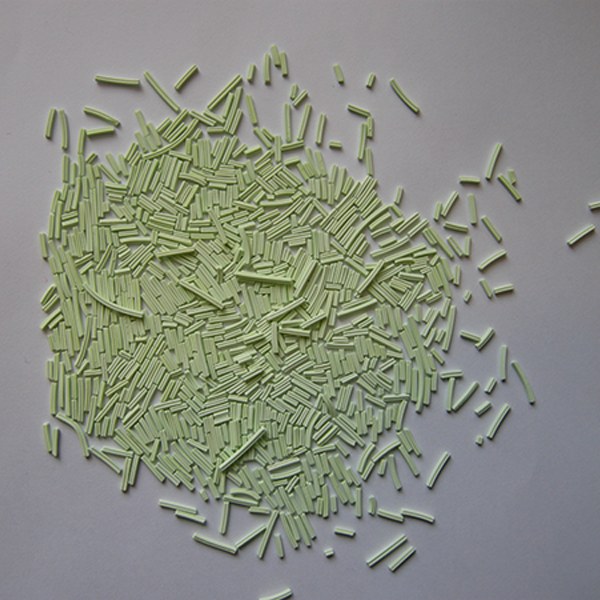

Product detail pictures:

Related Product Guide:

We are ready to share our knowledge of marketing worldwide and recommend you suitable products at most aggressive costs. So Profi Tools offer you finest benefit of money and we are ready to produce alongside one another with OEM Customized Ethanol Drying - Molecular Sieves – Gascheme , The product will supply to all over the world, such as: Pakistan, Egypt, Lyon, We are looking forward to cooperating closely with you to our mutual benefits and top development. We guaranteed quality, if customers were not satisfied with the products' quality, you can return within 7days with their original states.

Customer service staff and sales man are very patience and they all good at English, product's arrival is also very timely, a good supplier.

Write your message here and send it to us