Molecular sieves are a remarkable class of materials that have revolutionized various industries by providing efficient separation and purification processes. These highly porous materials, typically made from zeolites or synthetic compounds, possess uniform pore sizes that allow them to selectively adsorb molecules based on their size and shape. This unique property makes molecular sieves invaluable in applications ranging from gas separation to water purification and even in the pharmaceutical industry.

What Are Molecular Sieves?

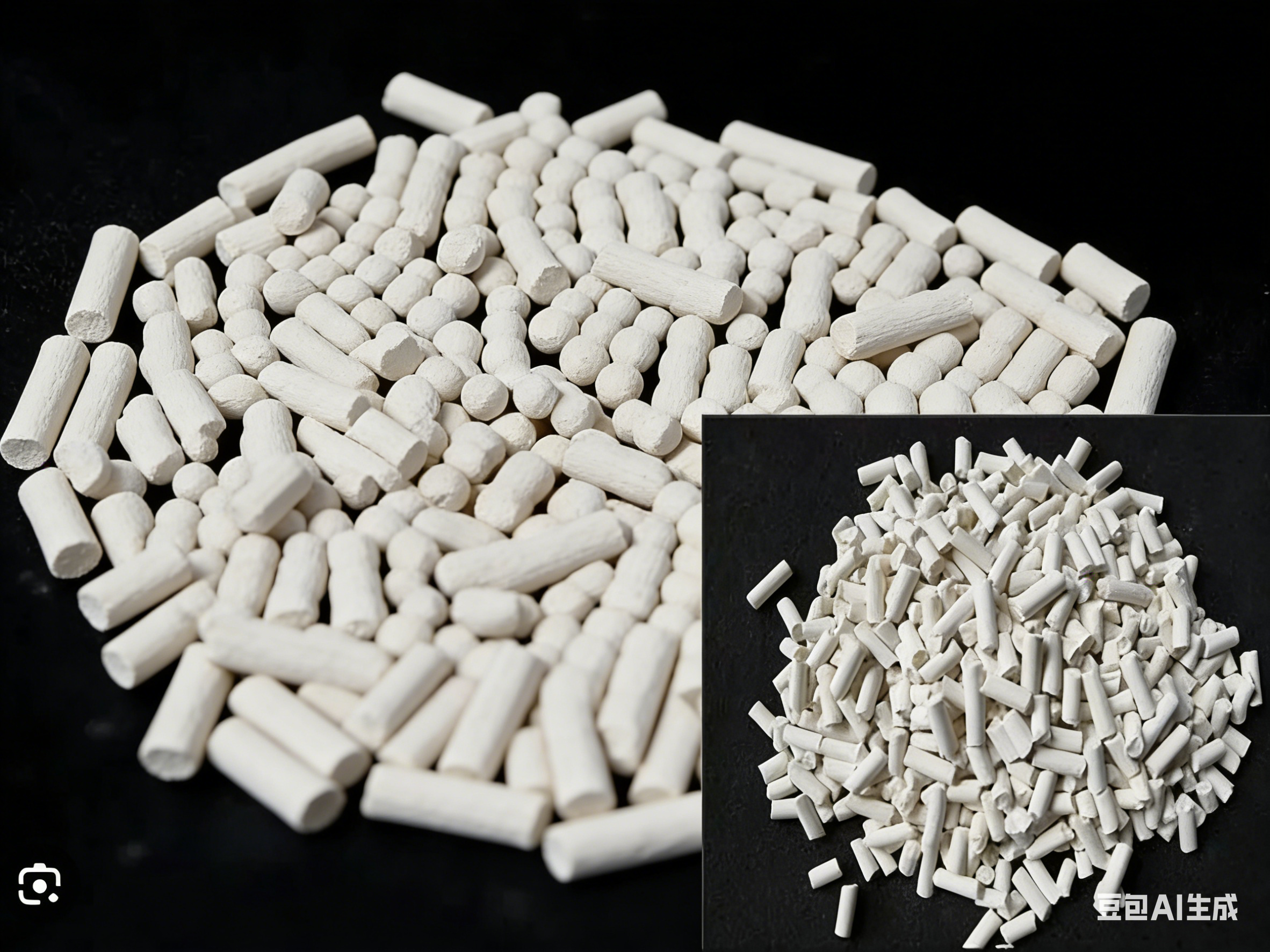

At their core, molecular sieves are crystalline structures with a network of pores that can trap specific molecules while allowing others to pass through. The most common types of molecular sieves are zeolites, which are naturally occurring minerals, and synthetic variants like silica gel and activated alumina. The pore sizes of these materials can be tailored during the manufacturing process, enabling them to target specific molecules for adsorption.

Applications of Molecular Sieves

1. Gas Separation: One of the most significant applications of molecular sieves is in the separation of gases. Industries utilize these materials to separate nitrogen from oxygen in air, producing high-purity nitrogen for various applications, including food packaging and electronics manufacturing.

2. Water Purification: Molecular sieves play a crucial role in water treatment processes. They can effectively remove contaminants such as heavy metals, organic compounds, and even microorganisms, ensuring that water meets safety standards for consumption and industrial use.

3. Pharmaceuticals: In the pharmaceutical industry, molecular sieves are used to purify solvents and separate active pharmaceutical ingredients (APIs) from impurities. Their ability to selectively adsorb specific molecules enhances the efficiency of drug production and ensures the quality of the final product.

4. Petrochemical Industry: Molecular sieves are essential in refining processes, where they help separate hydrocarbons based on size and shape. This separation is critical for producing high-quality fuels and chemicals.

5. Food and Beverage: In the food industry, molecular sieves are used to remove unwanted flavors and odors from products, ensuring a better taste and quality. They are also employed in the packaging of food items to extend shelf life by controlling moisture levels.

Choosing the Right Molecular Sieve

When selecting a molecular sieve for a specific application, several factors must be considered, including pore size, adsorption capacity, and chemical stability. Common pore sizes include 3A, 4A, and 5A, each designed to target different types of molecules. For instance, a 3A sieve is ideal for adsorbing small molecules like water, while a 5A sieve can capture larger molecules such as hydrocarbons.

The Future of Molecular Sieves

As industries continue to seek more efficient and sustainable solutions, the demand for molecular sieves is expected to grow. Innovations in material science are paving the way for the development of new types of molecular sieves with enhanced properties, such as increased selectivity and improved thermal stability. These advancements will further expand the applications of molecular sieves, making them an essential component in the quest for cleaner and more efficient industrial processes.

Conclusion

Molecular sieves are more than just materials; they are powerful tools that enhance efficiency and sustainability across various sectors. By understanding their properties and applications, businesses can leverage molecular sieves to improve their processes, reduce waste, and ultimately deliver better products to consumers. As technology advances, the potential for molecular sieves will only continue to grow, solidifying their place as a cornerstone in modern industrial applications.

Post time: Dec-10-2025