In the ever-evolving landscape of industrial processes, the demand for efficient gas separation technologies has never been more critical. Enter Carbon Molecular Sieves (CMS), a revolutionary material that is transforming the way industries approach gas separation and purification. With their unique properties and capabilities, CMS are becoming indispensable in various applications, from natural gas processing to air separation.

What are Carbon Molecular Sieves?

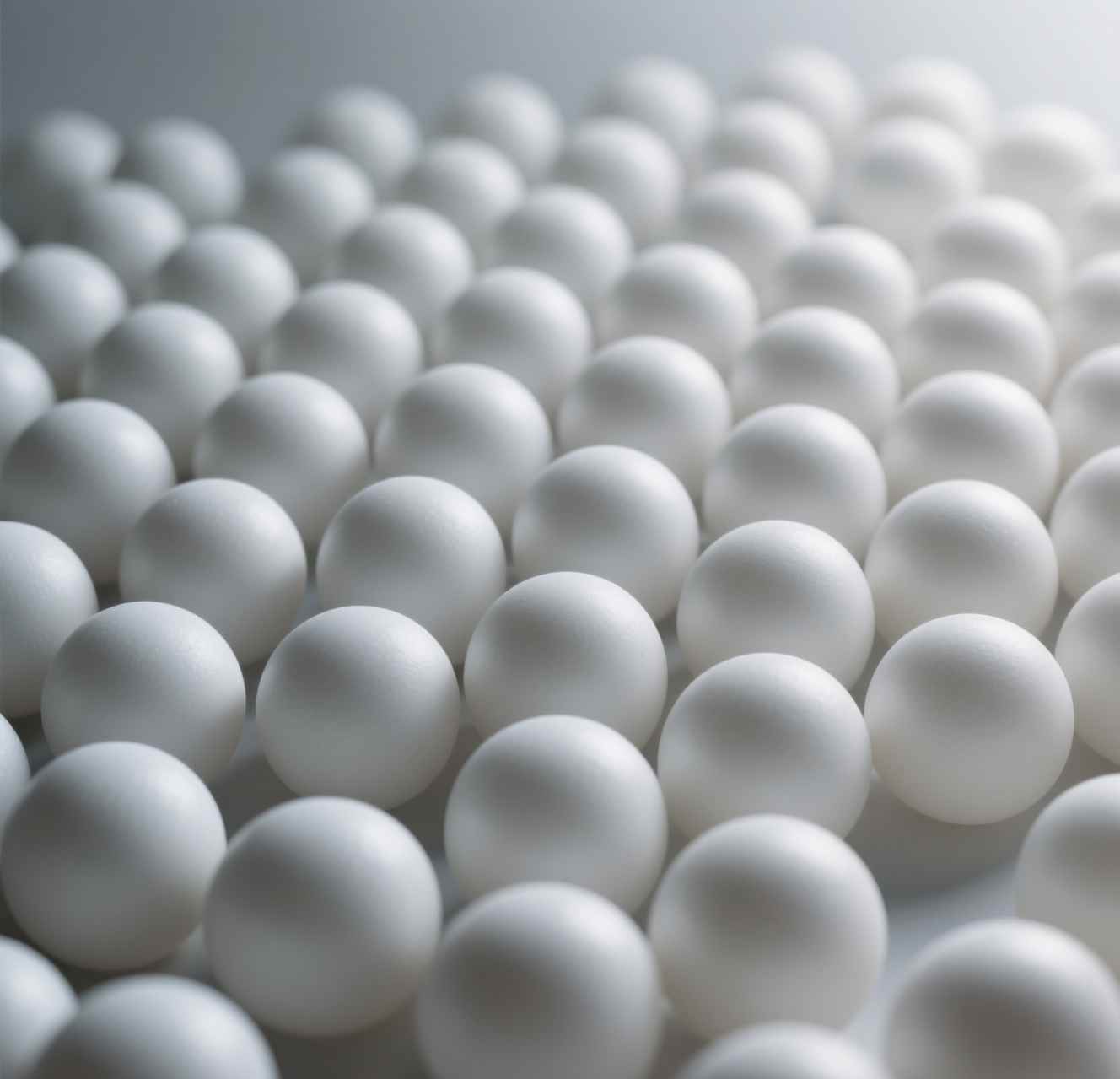

Carbon Molecular Sieves are porous carbon materials characterized by their ability to selectively adsorb molecules based on size and shape. These sieves are engineered to create a network of pores that can effectively separate gases, making them ideal for applications where precision and efficiency are paramount. The unique structure of CMS allows them to discriminate between different gas molecules, enabling the separation of smaller molecules from larger ones with remarkable accuracy.

Applications of Carbon Molecular Sieves

The versatility of CMS is evident in their wide range of applications. In the natural gas industry, CMS are employed to remove impurities such as carbon dioxide and water vapor, ensuring that the gas meets stringent quality standards before it reaches consumers. In the field of air separation, CMS play a crucial role in the extraction of oxygen and nitrogen from the atmosphere, providing essential gases for medical, industrial, and environmental applications.

Moreover, CMS are increasingly being utilized in the production of hydrogen, a clean energy source that is gaining traction in the fight against climate change. By efficiently separating hydrogen from other gases, CMS contribute to the development of sustainable energy solutions that can power the future.

Advantages of Using Carbon Molecular Sieves

One of the standout features of Carbon Molecular Sieves is their high selectivity and efficiency. Unlike traditional separation methods, which often rely on energy-intensive processes, CMS operate at lower temperatures and pressures, significantly reducing operational costs. Additionally, their robust structure ensures a long lifespan, minimizing the need for frequent replacements and maintenance.

Furthermore, CMS are environmentally friendly, as they do not require harmful chemicals for their operation. This aligns with the growing trend towards sustainable practices in industrial processes, making CMS an attractive option for companies looking to enhance their green credentials.

The Future of Carbon Molecular Sieves

As industries continue to seek innovative solutions to meet the challenges of gas separation, the future of Carbon Molecular Sieves looks promising. Ongoing research and development are focused on enhancing the performance of CMS, exploring new applications, and optimizing their production processes. With advancements in nanotechnology and material science, the potential for CMS to revolutionize gas separation is limitless.

In conclusion, Carbon Molecular Sieves are not just a technological advancement; they represent a paradigm shift in how industries approach gas separation. Their unique properties, coupled with their environmental benefits, position CMS as a key player in the quest for efficiency and sustainability. As we move towards a greener future, the role of Carbon Molecular Sieves will undoubtedly become more prominent, paving the way for innovative solutions that meet the demands of a rapidly changing world.

Post time: Jun-25-2025