Manufacturer for PSA Nitrogen Gas Plant - Carbon Molecular Sieve (CMS) – Gascheme

Manufacturer for PSA Nitrogen Gas Plant - Carbon Molecular Sieve (CMS) – Gascheme Detail:

| Applications | Material | Size (mm) | Shape | |

| SGC-L | PSA Nitrogen, Shale gas purifying | Carbon@promotor | 1.4~1.7 | E |

| SGC-M | PSA Nitrogen, Shale gas purifying | Carbon@promotor | 1.4~1.7 | E |

| SGC-HA | PSA Nitrogen, Shale gas purifying | Carbon@promotor | 1.4~1.7 | E |

| SGC-HB | PSA Nitrogen, Shale gas purifying | Carbon@promotor | 1.4~1.7 | E |

Remark

Shape: E-cylindrical extrudate

Form: Activated

Our serial carbon molecular sieves can satisfy all your PSA nitrogen processing for normal purity nitrogen (99.5%), high purity nitrogen (99.9%) and ultra-high purity nitrogen (99.99%).

Also, our CMS can be used for purifying of natural gas and coal gas.

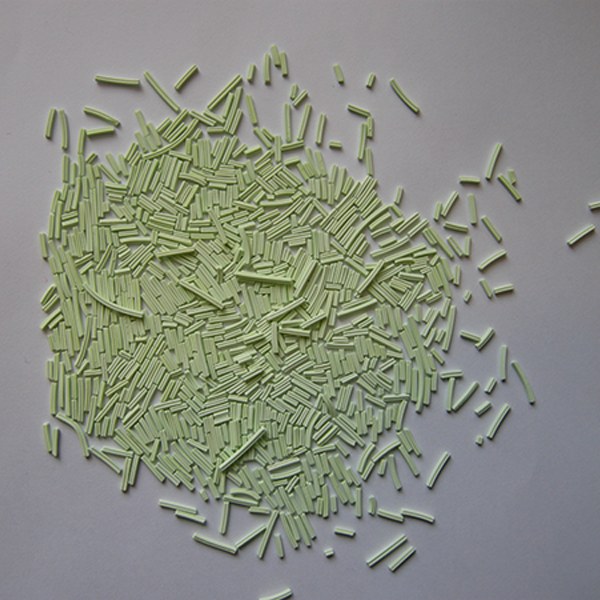

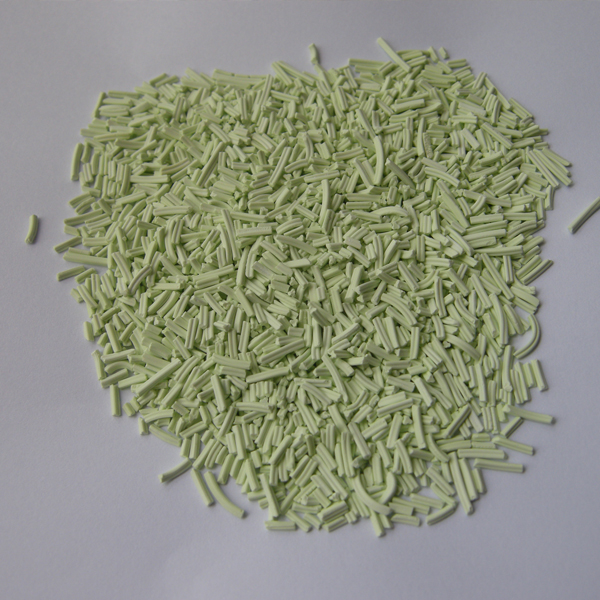

Product detail pictures:

Related Product Guide:

We know that we only thrive if we can guarantee our combined price competiveness and quality advantageous at the same time for Manufacturer for PSA Nitrogen Gas Plant - Carbon Molecular Sieve (CMS) – Gascheme , The product will supply to all over the world, such as: Borussia Dortmund, Iran, Iran, We warmly welcome domestic and overseas customers to visit our company and have business talk. Our company always insists on the principle of "good quality, reasonable price, the first-class service". We are willing to build long-term, friendly and mutually beneficial cooperation with you.

Company director has very rich management experience and strict attitude, sales staff are warm and cheerful, technical staff are professional and responsible,so we have no worry about product,a nice manufacturer.

Write your message here and send it to us