2020 High quality N2/O2 Separation - Molecular Sieves – Gascheme

2020 High quality N2/O2 Separation - Molecular Sieves – Gascheme Detail:

| Applications | Material | Size (mm) | Shape | |

| 3A(GC-328) | Drying of natural gas and hydrocarbon streams | Zeolite | 1.6~2.5 | S |

| 3A(GC-335) | Drying of natural gas and hydrocarbon streams | Zeolite | 3~5 | S |

| 3A(GC-341) | Drying of cracked gas and hydrocarbon streams | Zeolite | 1.6 and 3.0 | E |

| 4A(GC-412) | Drying of solvents | Zeolite | 0.5~1.0 | S |

| 4A(GC-428) | Drying of natural gas and hydrocarbon streams | Zeolite | 1.6~2.5 | S |

| 4A(GC-437) | Drying of air, natural gas and hydrocarbon streams | Zeolite | 4~6 | S |

| 4A(GC-441) | Drying of natural gas | Zeolite | 1.6 and 3.0 | E |

| 5A(GC-528) | Natural gas sweetening, Purifying of H2 | Zeolite | 1.6~2.5 | S |

| 5A(GC-528C) | Removal of H2S and light mercaptans from Natural gas, CO/.CO2 from H2, N2/O2 seperation | Zeolite | 1.6 and 3.0 | E |

| 5A(GC-532) | Separation i/n paraffins | Zeolite | 2~3 | S |

| 5A(GC-532A) | Natural gas sweetening | Zeolite | 3~5 | S |

| 13X(GC-928) | Drying and sweetening of natural gas andLPG streams, air purifying | Zeolite | 1.6~2.5 | S |

| 13X(GC-935) | Drying and sweetening of natural gas, air purifying | Zeolite | 3~5 | S |

| 13X(GC-938) | Drying and sweetening of natural gas, air purifying | Zeolite | 4~6 | S |

| 13X(GC-941) | Drying and sweetening of natural gas andLPG streams, air purifying | Zeolite | 1.6 and 3.0 | E |

| 13X-HP | Seperation i/n paraffins, PSA O2 | Zeolite | 1.6~2.5 | S |

| XH-5 | Refrigerant R600a,R290,R12,R123,R124,R125 | Zeolite | 1.6~2.5 | S |

| XH-7 | Refrigerant R290,R12,R123,R124,R125,R134a | Zeolite | 1.6~2.5 | S |

| XH-9 | Refrigerant R123,R124,R125,R134a,R143a,R152a | Zeolite | 1.6~2.5 | S |

Remark

Shape: S-sphere E-cylindrical extrudate

Form: 1-Oxide

Our molecular sieves can satisfy your applications for Cryogenic air separation units (ASUs) are built to provide nitrogen or oxygen and often co-produce argon, natural gas dehydration and sweetening, hydrogen purifying in PSA processing, medical & industrial oxygen in PSA/VPSA processing, air braking system. dehydration of hydrocarbon gas or liquid (No Olefins Present), dehydration of hydrocarbon gas or liquid (With Olefins Present), isomerization processes, Feedstock Purification, LPG Desulfurization,

n/i-Paraffin separation, butane destenching, MTBE / TAME, reformer applications, FCC off gas dehydration.

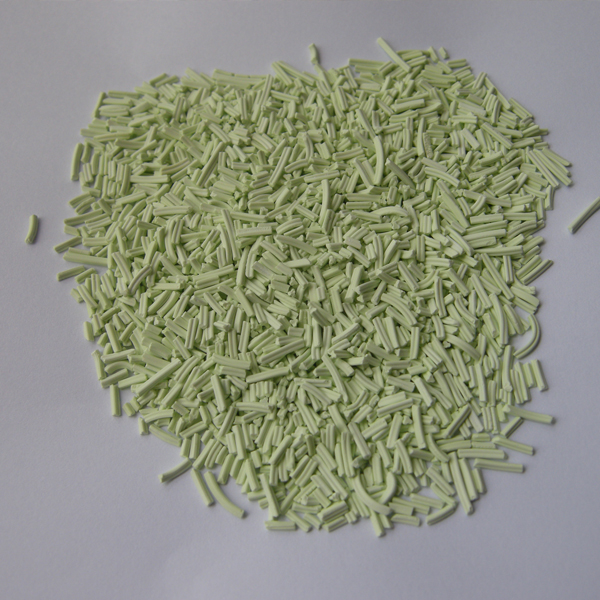

Product detail pictures:

Related Product Guide:

We aim to find out quality disfigurement from the production and supply the best service to domestic and overseas customers wholeheartedly for 2020 High quality N2/O2 Separation - Molecular Sieves – Gascheme , The product will supply to all over the world, such as: Istanbul, Manchester, Namibia, Good quality and reasonable price have brought us stable customers and high reputation. Providing 'Quality Products, Excellent Service, Competitive Prices and Prompt Delivery', we are now looking forward to even greater cooperation with overseas customers based on mutual benefits. We'll work whole-heartedly to improve our solutions and services. We also promise to work jointly with business partners to elevate our cooperation to a higher level and share success together. Warmly welcome you to visit our factory sincerely.

Managers are visionary, they have the idea of "mutual benefits, continuous improvement and innovation", we have a pleasant conversation and Cooperation.

Write your message here and send it to us